In the printer's movement menu - we check the operation of the axes, pull it back and forth, at the same time we check the stop on the operation of the trailer. If everything "rolls" correctly and does not hurt anything, then you can try to print. Level a table, it is better on several points. Be sure to check the operation of the axes, the direction of movement of the axes, the operation of the limit switches and the working out of the Home command before starting. Everything is standard, you can buy and change in case of failure.īefore printing, you should check all the nodes for proper operation, check the movements, check the operation of the heating nodes, extruding, level the table. The radiator is compact, for cooling, the heating block is standard, nozzles are like MK8. As a hot end, an aluminum hot end with a radiator, a thermal barrier, a heating block similar to CR-10 is used. The effector assembly is assembled, hidden under a protective metal casing. Control board cover - USB-B socket and microSD card slot visible. It is fixed decently - without distortions, the screws are installed in the holes. All connectors are different, it is very difficult to mix up. Yellow tags - marking of the axes for which the harnesses are intended. They are tough, but they fulfill their function.

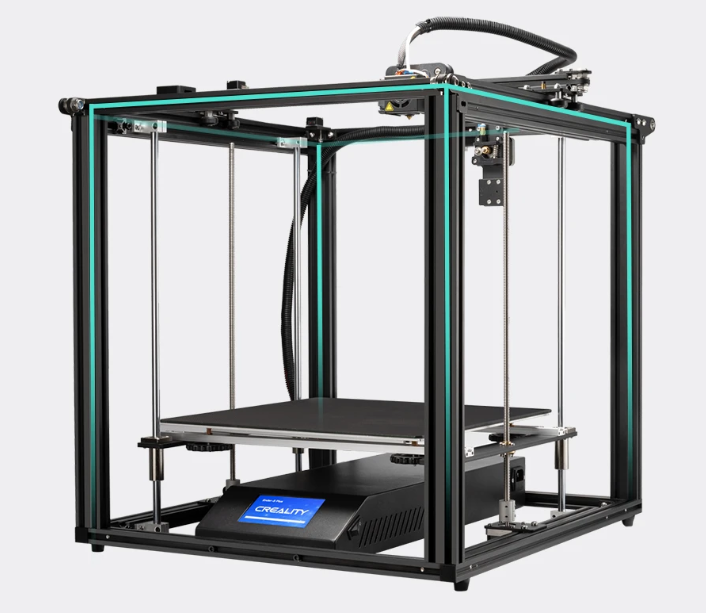

The base for the printer is already assembled. The control board is under the cover, the power supply is located under the frame. Corrugated hoses with wires inside are clearly visible. The main feature of the printer is a vertical display in a metal case. It is connected with a small connector, if desired, you can transfer the installation to another place, after extending the wire. Size 235 x 235 mm. It is an aluminum base of type MK3 with installed glass with an adhesive coating. The printing platform goes separately, in a transport film.

#Cube pro imprimante 3d plus

A big plus is that such complex nodes are already assembled and do not need to be configured. The large carriage has an installed X-axis trailer and an extruder mechanism. The photo shows carriages that will move the X axis up and down. The axles are driven by conventional Nema17 engines.

#Cube pro imprimante 3d install

The user will have to assemble the upper U-shaped part of the frame, plus assemble the carriages and effector on the X axis, install the axis on the frame, connect the wires and carry out the initial setup. The base is completely assembled - electronics, the lower part of the frame with racks, X- and Z-axes carriages, an extruder, the Y axis is completely with a table mount, and all cables. The extended version, plus the files go to the bundled flash drive (in the photo, the card reader and memory card). Together with the printer, detailed assembly instructions are supplied, with a visual representation of what and where to collect. Inside, the box contains spare parts and an assembled printer base.Īnother important point. The power supply is carefully placed under the structure. The printing process on such a printer looks like the simultaneous movement of the table along Y, the head along X and the periodic elevation of the screw by Z.Įlectronics is placed in a separate box under a metal cover. The display is mounted on the left stand. The coil holder is located on the top bar.

This is an indication of a movable platform, a proven design for years.

The appearance of the printer is the usual Prusa i3 on the profile. Accordingly, both support and firmware are suitable from Longer3D. Specifically, this is an OEM printer from Longer3D, and specifically the LK4 Pro model, the top in the line of Prusa i3 clones on the profile. Thirdly, the printer has a print area size "slightly larger" than standard ones: namely 220 x 220 x 250 mm.Īnother important point is the brand printer. This allows printing with nylon, PET, flex and TPU. A normal metal extruder with adaptation to soft materials, a special glass on the platform with an adhesive coating, and powerful blowing of the model were installed. Secondly, the printer allows you to print multiple materials, not just ABS / PLA. Alfawise U30 Pro is a great inexpensive option for beginners in 3D printing.įirstly, it can do “a little more” for money comparable to the rest, namely: a filament sensor, the function of resuming printing after a stop, quiet TMC2208 drivers, cable management, a rigid frame from profile 2040, metal carriages and printing with USB / MicroSD.

0 kommentar(er)

0 kommentar(er)